RTO – Kulaylka Sarrifka Sheeramka Malabka

Hawlaha

1.Yaree luminta kulaylka ee gaasta qiiqa, iyo hagaajinta waxtarka shidaalka si loo badbaadiyo tamarta sida.

2.Enhance heerkulka gubanaya ku salaysan aragtida, hagaajinta gubashada atmospheric, la kulmaan heerkulka sare ee qalabka kulaylka weyn shidaalka qiimaha hoose ee calorific, gaar ahaan kala duwan codsiga ee foornooyinka qaraxa, wanaajiso hufnaanta shidaalka qiimaha calorific iyo in la yareeyo qiiqa ka soo gaaska hoose qiimaha calorific.

3.Hagaajinta shuruudaha kuleyliyaha kuleyliyaha, kordhinta wax soo saarka qalabka, kor u qaadida tayada alaabta iyo hoos u dhigida dib-u-maalgelinta qalabka.

4.Yaree qiiqa sii daaya qalabka kulaylka, yaraynta wasakhowga hawada iyo hagaajinta deegaanka.

Astaamaha

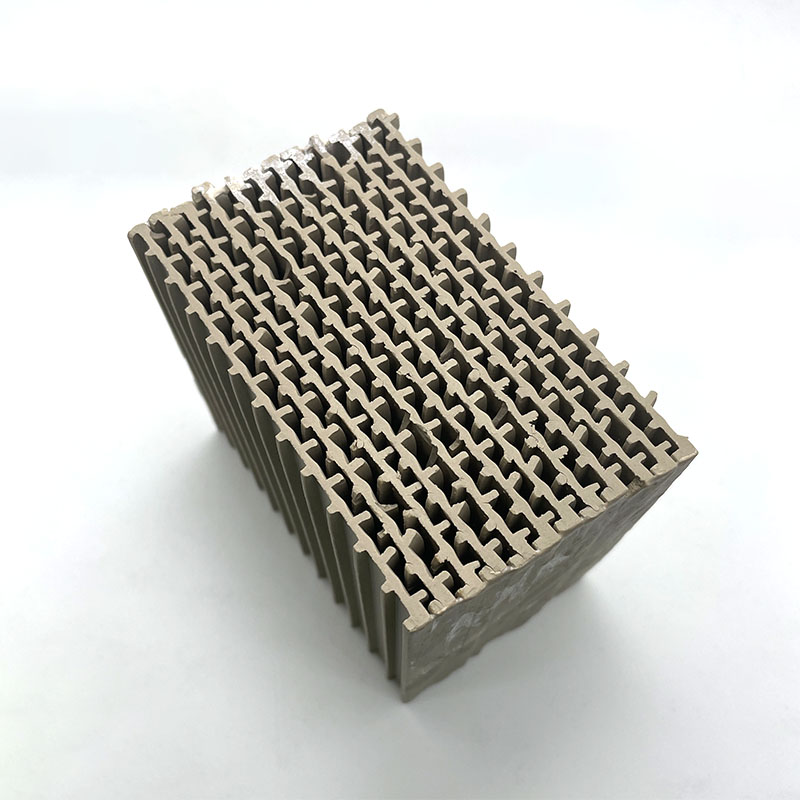

Astaamaha dib-u-dhaqaajinta dhoobada malabka waa sida soo socota: waxay leeyihiin balaadhinta kulaylka hooseeya, awoodda kulaylka gaarka ah ee sarreeya, meel sare oo gaar ah, hoos u dhigista cadaadiska hooseeya, caabbinta kulaylka hooseeya, kulaylka wanaagsan ee kuleylka, kuleylka kuleylka u adkaysta iyo wax ka badan. Markaa, warshadaha birta iyo kiimikaad, waxa loo isticmaalaa HTAC ahaan, halka aynu isku darayno dib-u-warshadaynta kulaylka qiiqa, gubasho tayo sare leh iyo yaraynta NOx. Waxay noqotaa kayd tamar run ah waxayna hoos u dhigtaa Nox.

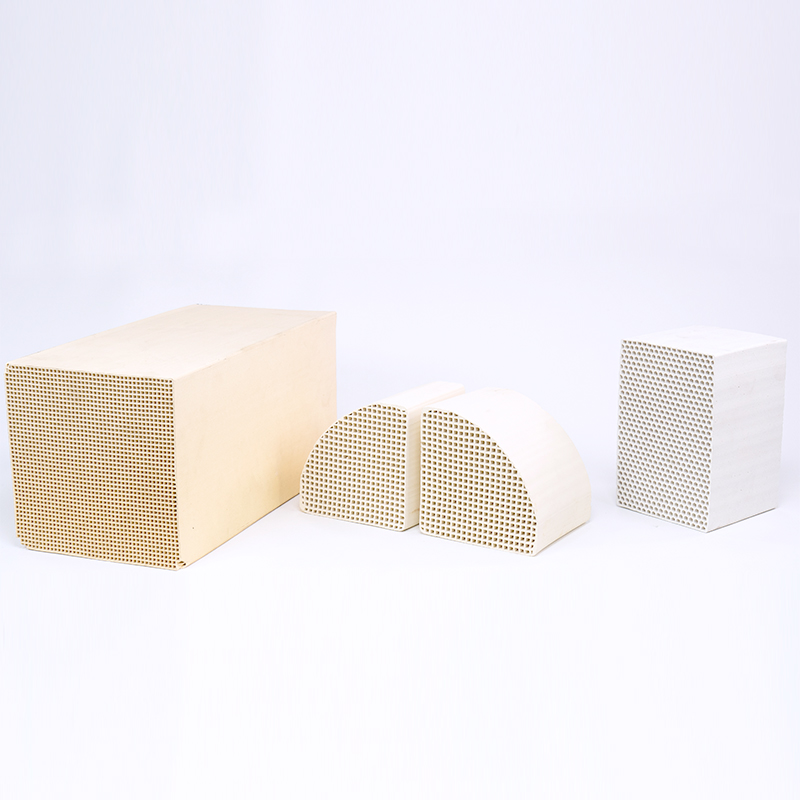

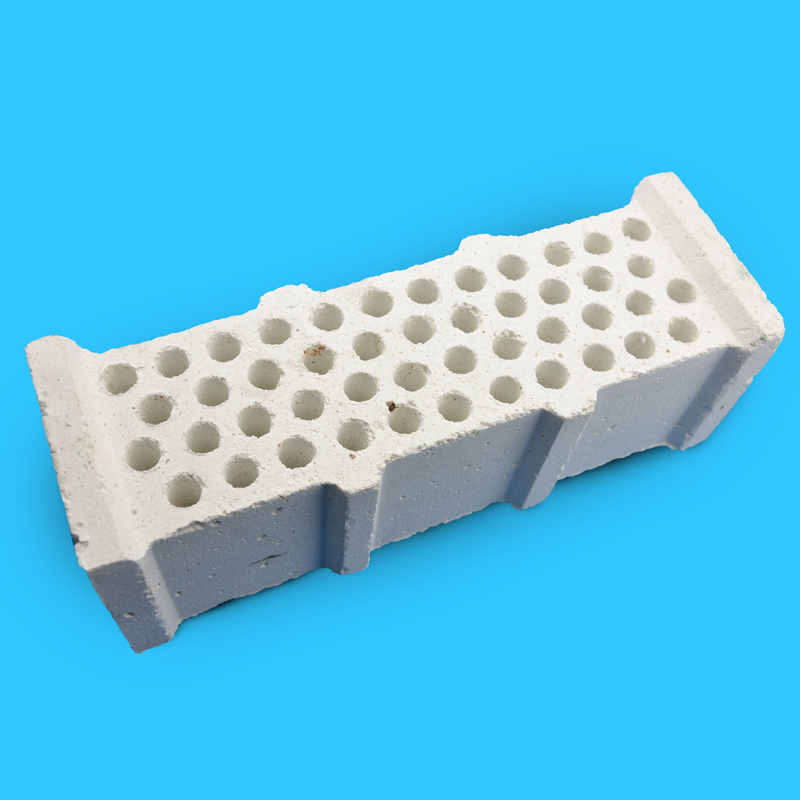

Qalabka: Alumina, Alumina cufan, Cordierite, Cordierite cufan, Mullite, Corundum Mullite iyo kuwa kale

Codsiga

dhoobada malabka waa furaha iyo qaybta xudunta u ah kaydinta kulaylka tignoolajiyada gubashada heerkul sare (teknoolajiyada HTAC). Waxaa si weyn loogu isticmaalay foornooyinka kululaynta birta ee kala duwan, foornooyinka kululaynta socodka, foornooyinka daaweynta kulaylka, foornooyinka been abuurka ah, foornooyinka dhalaalinta, roodhida dubaaniga / tundish, foornooyinka wax lagu qooyay, dableyda tuubada dhalaalaysa, iyo foornooyinka nooca gambaleelka ee warshadaha mishiinada biraha. Foornada, foornada qarxinta foornada hawada kulul; foornooyinka dhoobada kala duwan iyo foornooyinka dhalooyinka kala duwan ee warshadaha qalabka dhismaha; foornooyinka kululaynta tuubada kala duwan, foornooyinka dildilaaca iyo foornooyinka kale ee warshadaha ee warshadaha batroolka.

Tilmaamaha

100x100x100,100x150x150,150x150x150,150x150x300mm iyo kuwa kale

Tirada daloolka: 25x25,40x40,43x43,50x50,60x60 iyo kuwa kale

Cabirka

| Cabirka (mm) | Unugyada (N×N) | Cufnaanta Unugyada (CPSI) | Balaadhka Kanaalka (mm) | Dhumucda gidaarka gudaha (mm) | Qaybta Laanqayrta Xorta ah (%) |

| 150×150×300 | 20×20 | 11 | 6.00 | 1.35 | 64 |

| 150×150×300 | 25×25 | 18 | 4.90 | 1.00 | 67 |

| 150×150×300 | 32×32 | 33 | 3.70 | 0.90 | 63 |

| 150×150×300 | 40×40 | 46 | 3.00 | 0.70 | 64 |

| 150×150×300 | 43×43 | 50 | 2.80 | 0.65 | 64 |

| 150×150×300 | 50×50 | 72 | 2.40 | 0.60 | 61 |

| 150×150×300 | 59×59 | 100 | 2.10 | 0.43 | 68 |

Halabuurka Kiimikada

| Shayga | Cordierite | Mulite | Alumina Porcelain | Porcelain sare oo aluminium ah | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Kuwo kale | 1.5 | 14 | 3.7 | 8.3 | 5 |

Guryaha Jirka

| Shayga | Cordierite (Porous) | Mulite | Alumina Porcelain | Porcelain sare oo aluminium ah | Corundum | |

| Cufnaanta (g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Nuugista Biyaha (%) | 23 | 18 | 20 | 13 | 12 | |

| Isku-dhafka Balaadhinta kulaylka (× 10-6K-1) (20 ~ 800 ℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Kuleylka Gaarka ah (J/Kg.K) (20~1000℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| Habdhaqanka kulaylka (W/mk) (20 ~1000 ℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5~10 | |

| Max. Heerkulka shaqada (℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Awood burburin axial (MPa) | Qalalan | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Imika | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |